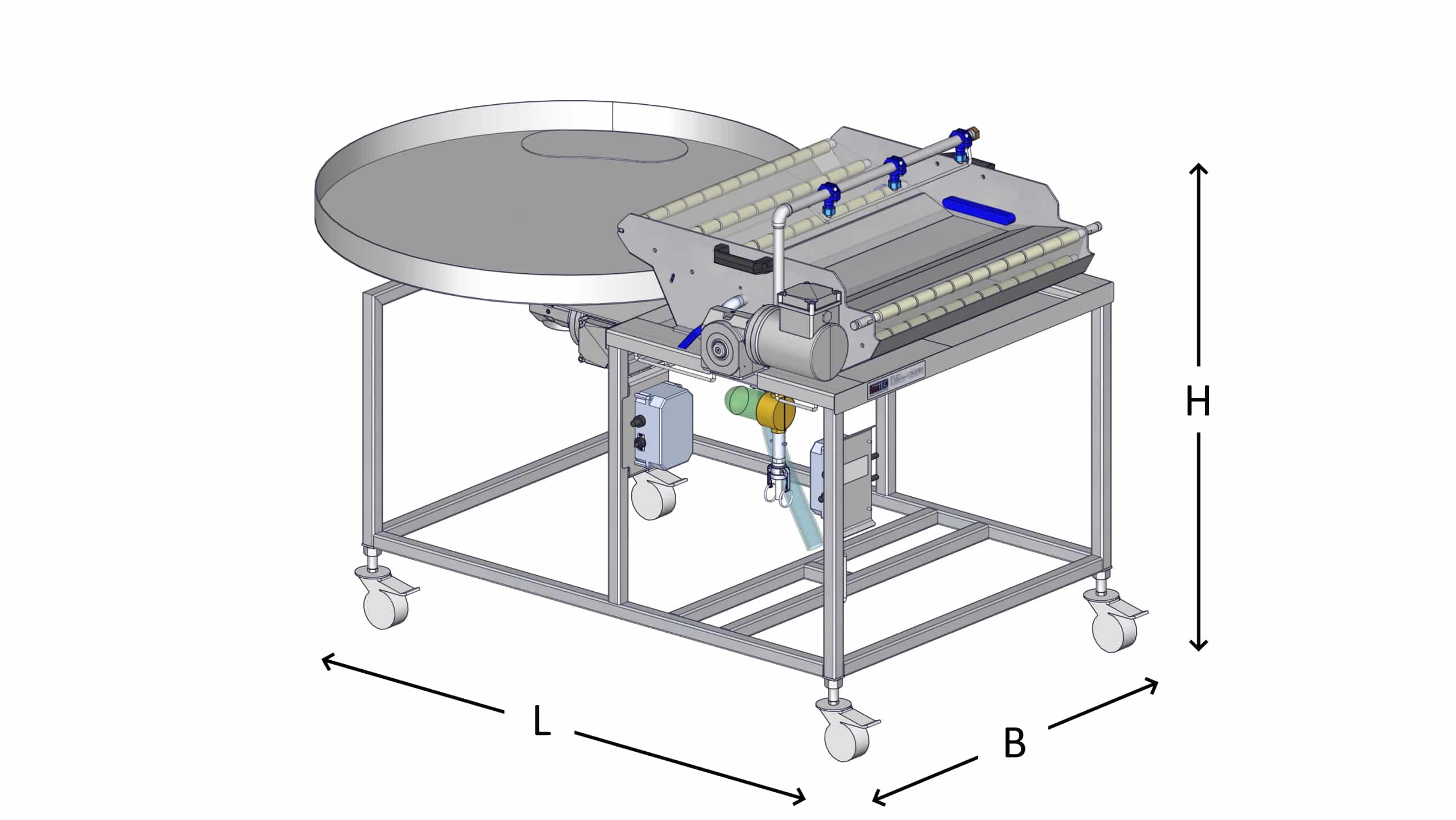

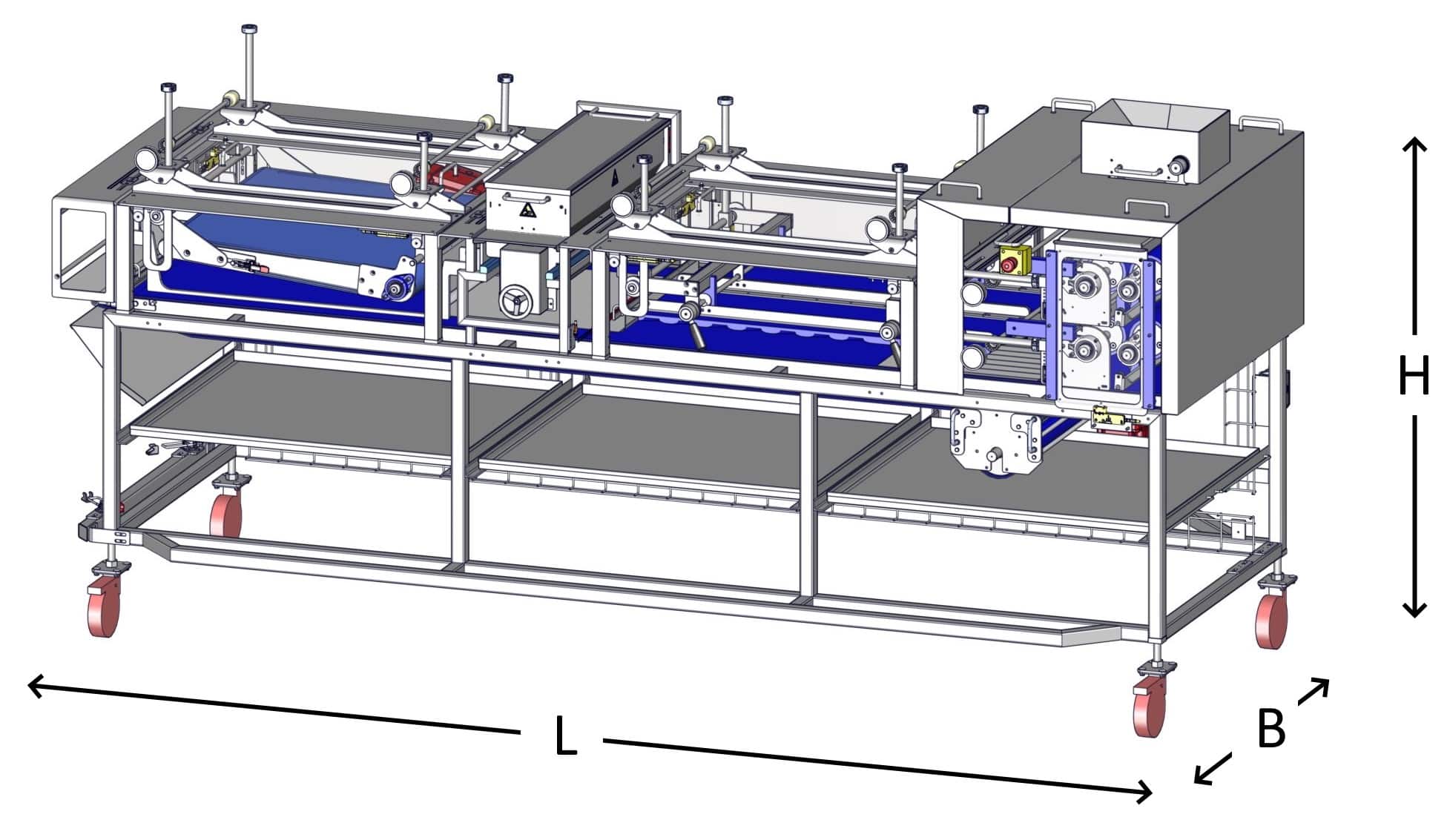

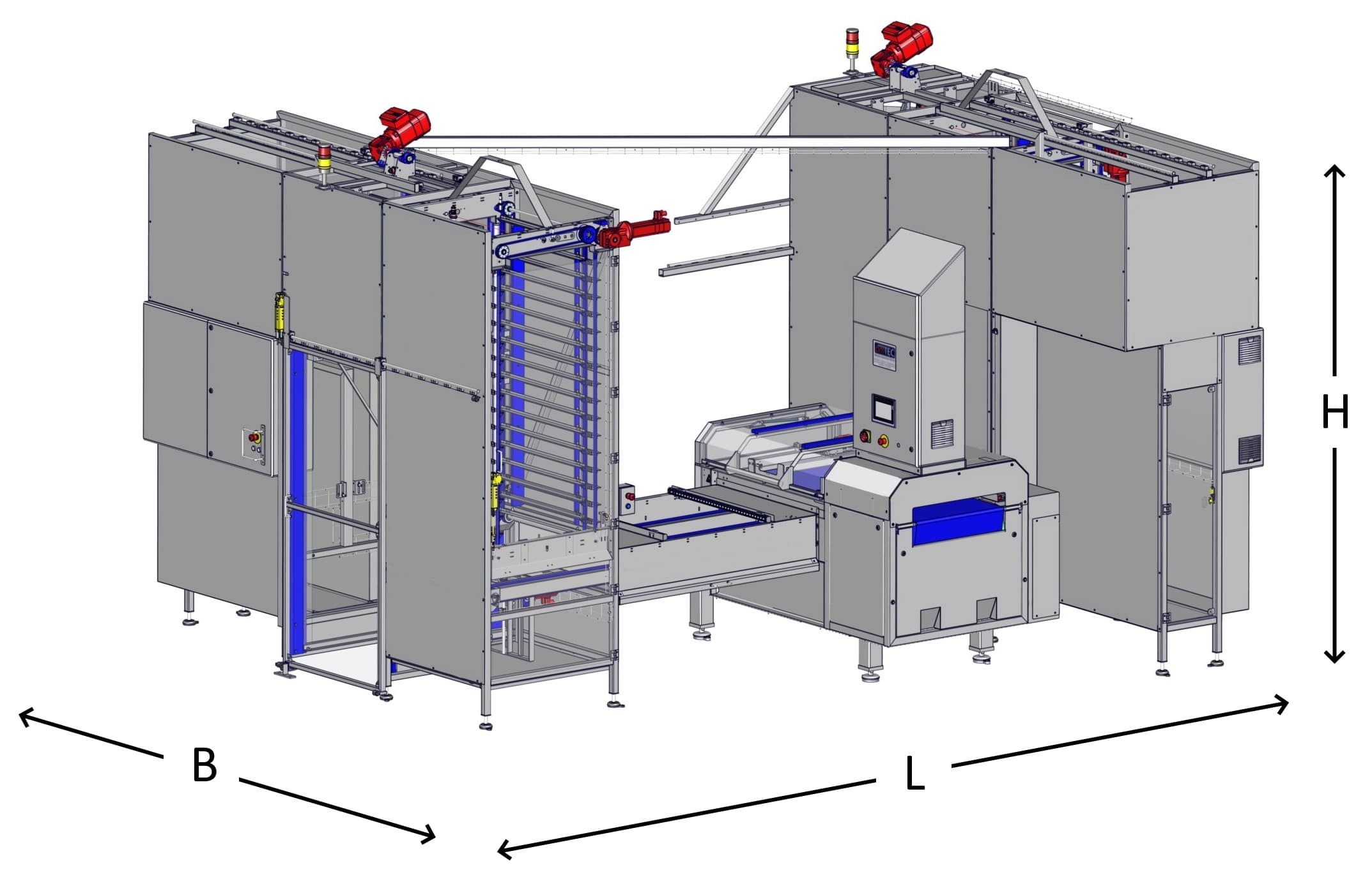

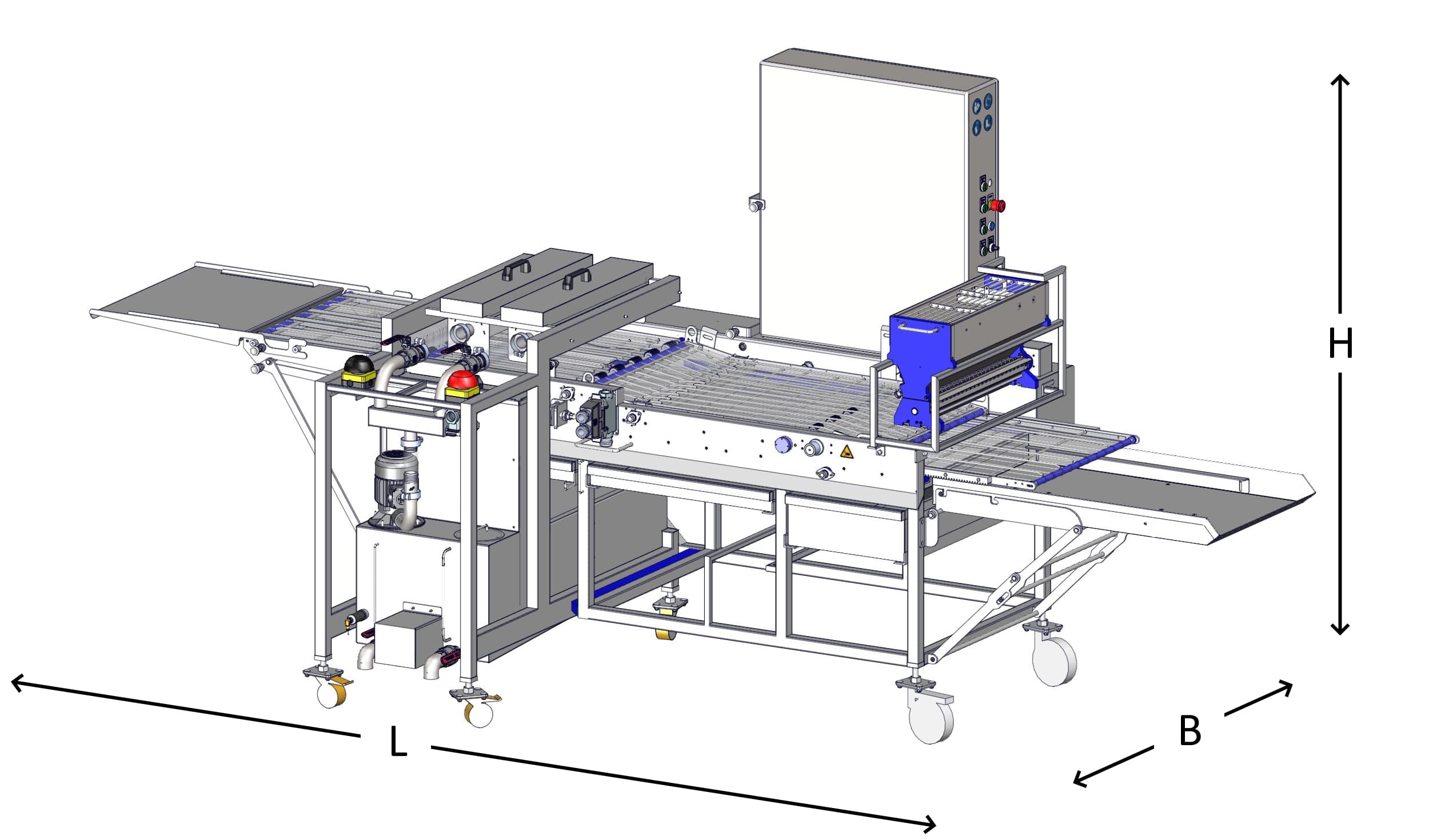

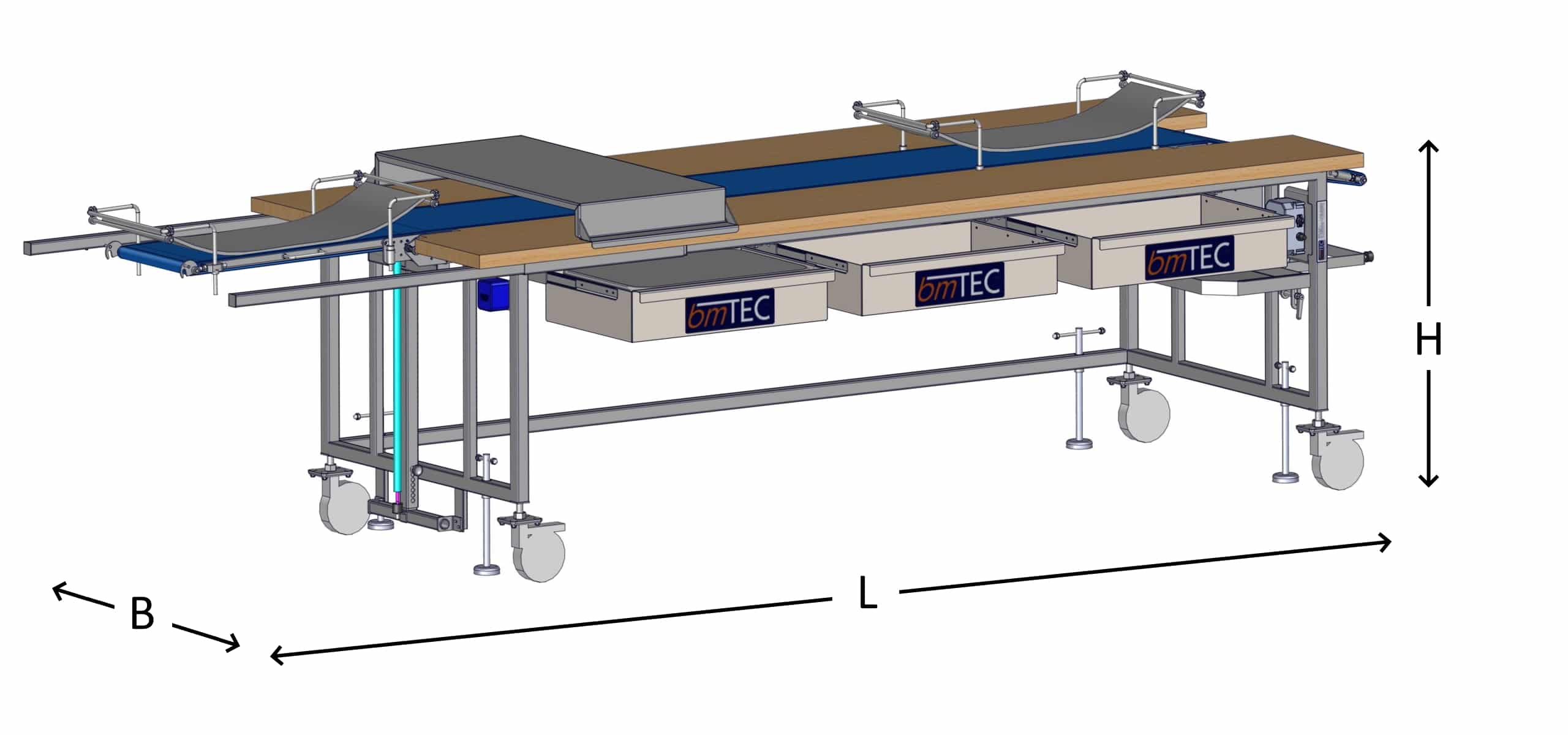

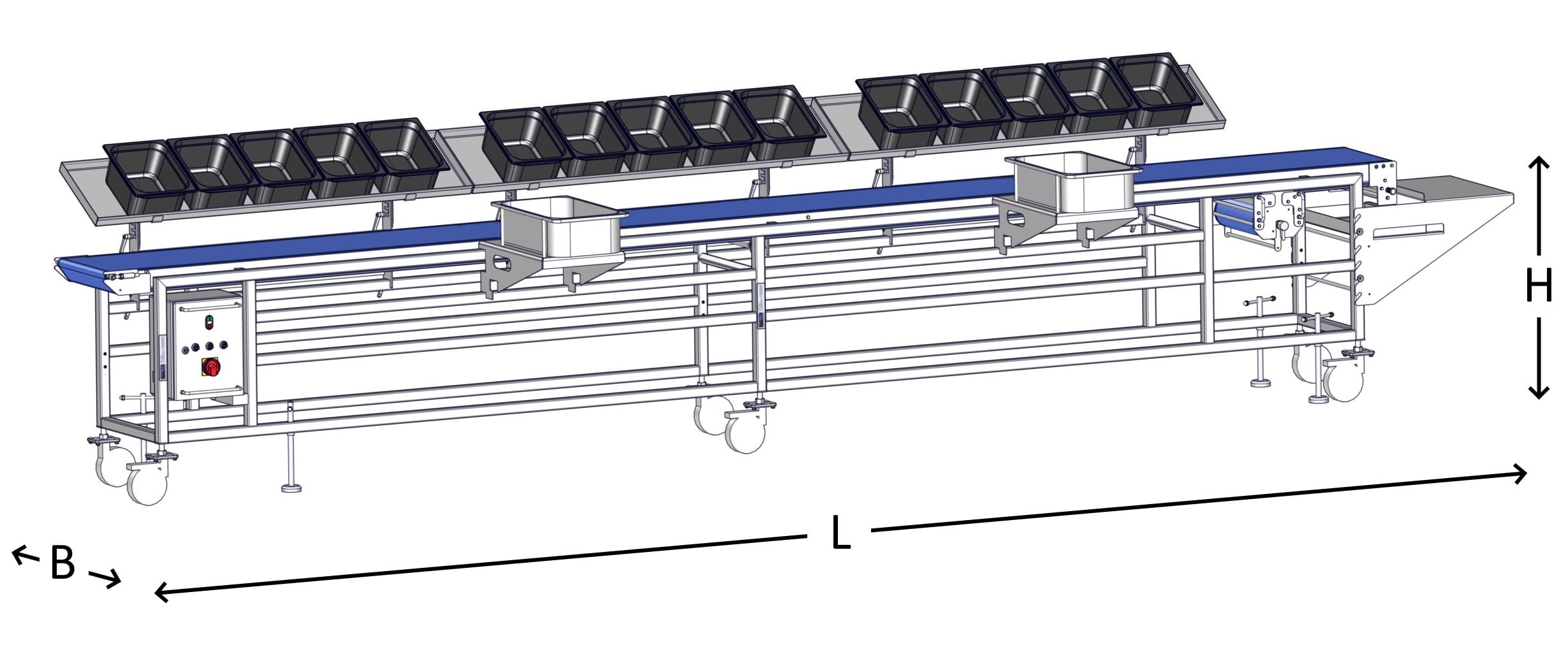

Je nach Produkt, Anspruch an Qualität und Verfügbarkeit von Mitarbeitern kann (oder muss) man nahezu jeden Teilschritt des gesamten Arbeitsprozesses zur Herstellung von Brot, Brötchen und Kleingebäck maschinell unterstützen bzw. gänzlich automatisieren. Nicht immer kann dies im Rahmen einer Gesamtplanung für einen Produktionsneuaufbau stattfinden.

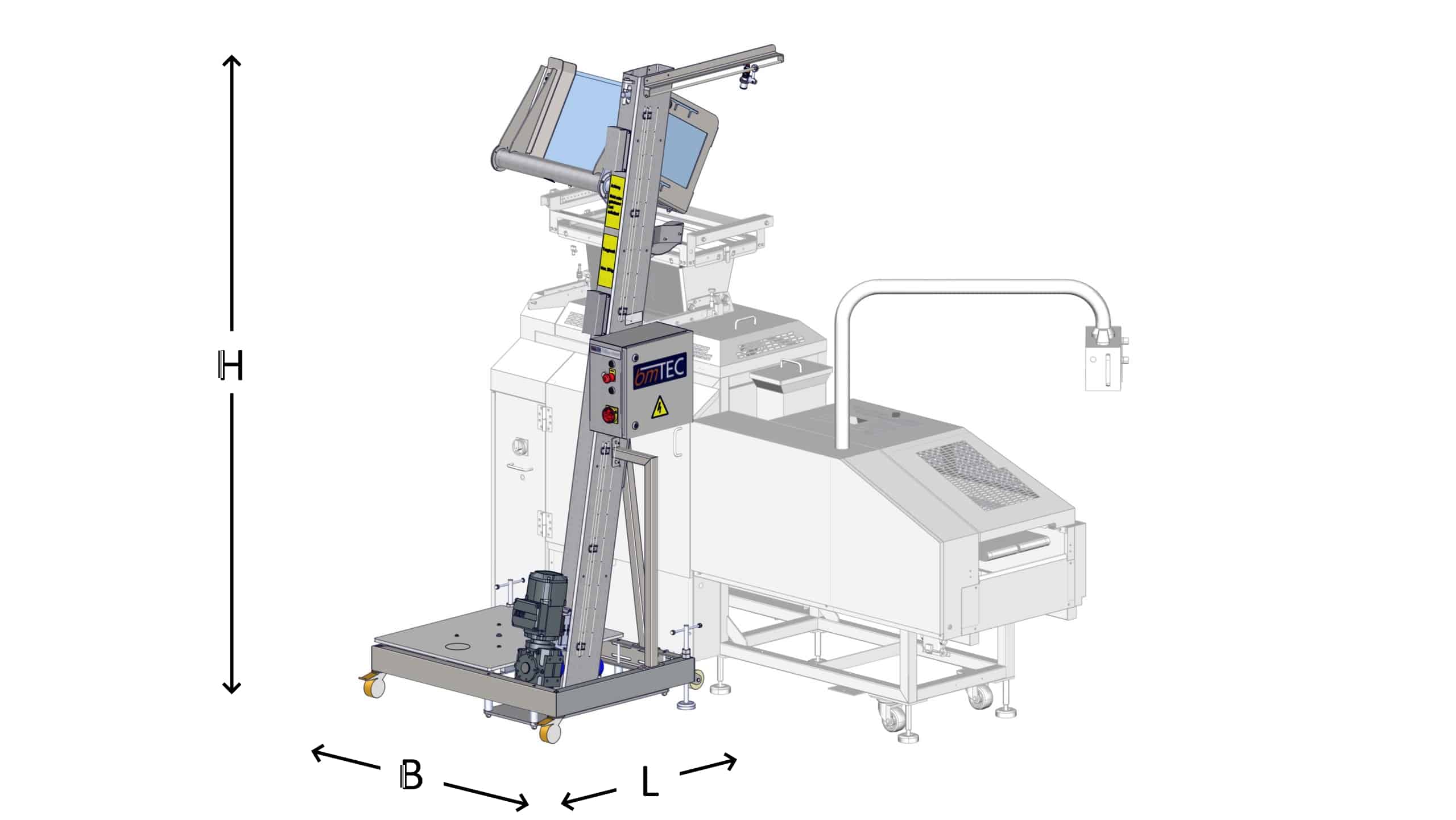

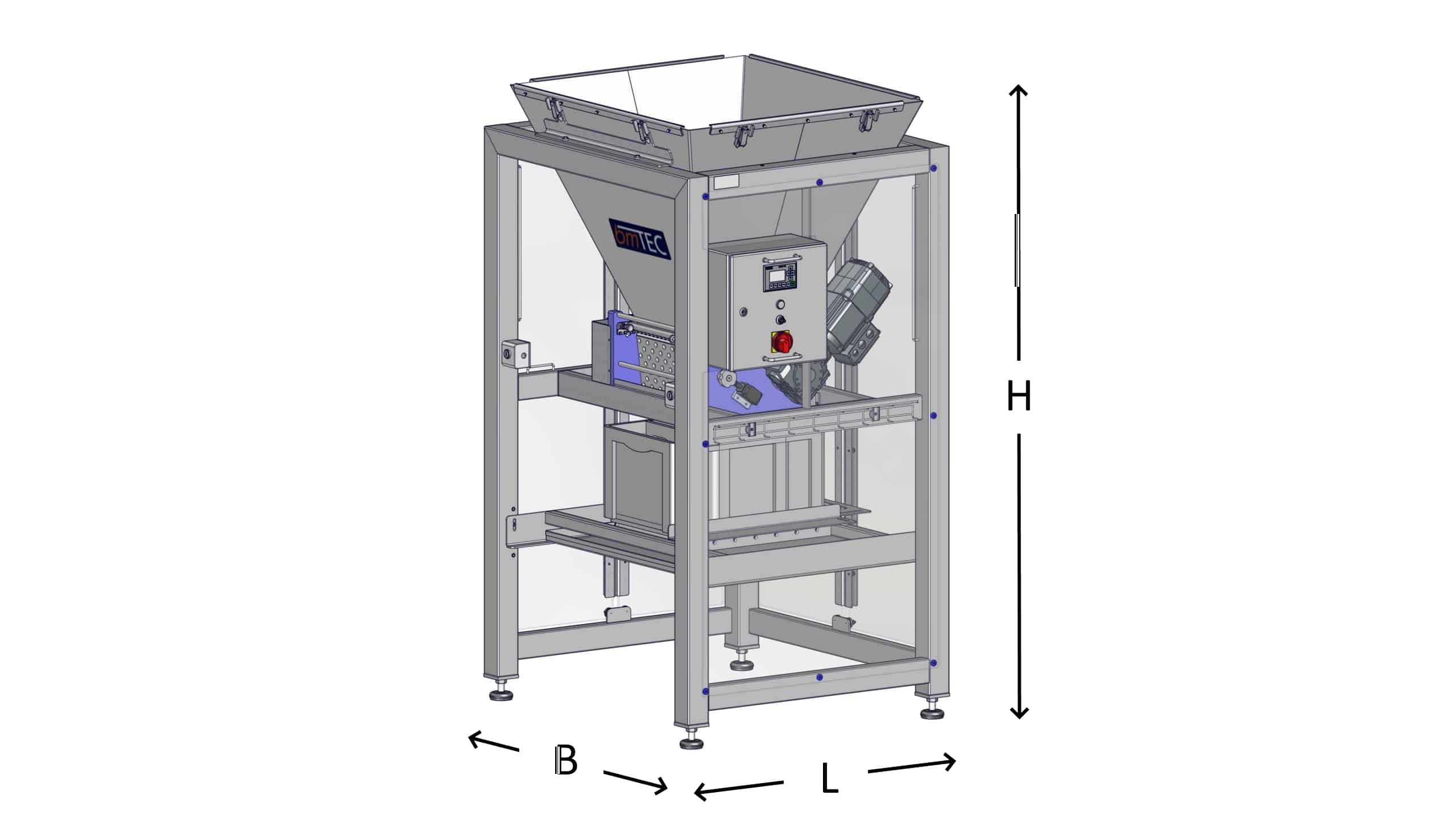

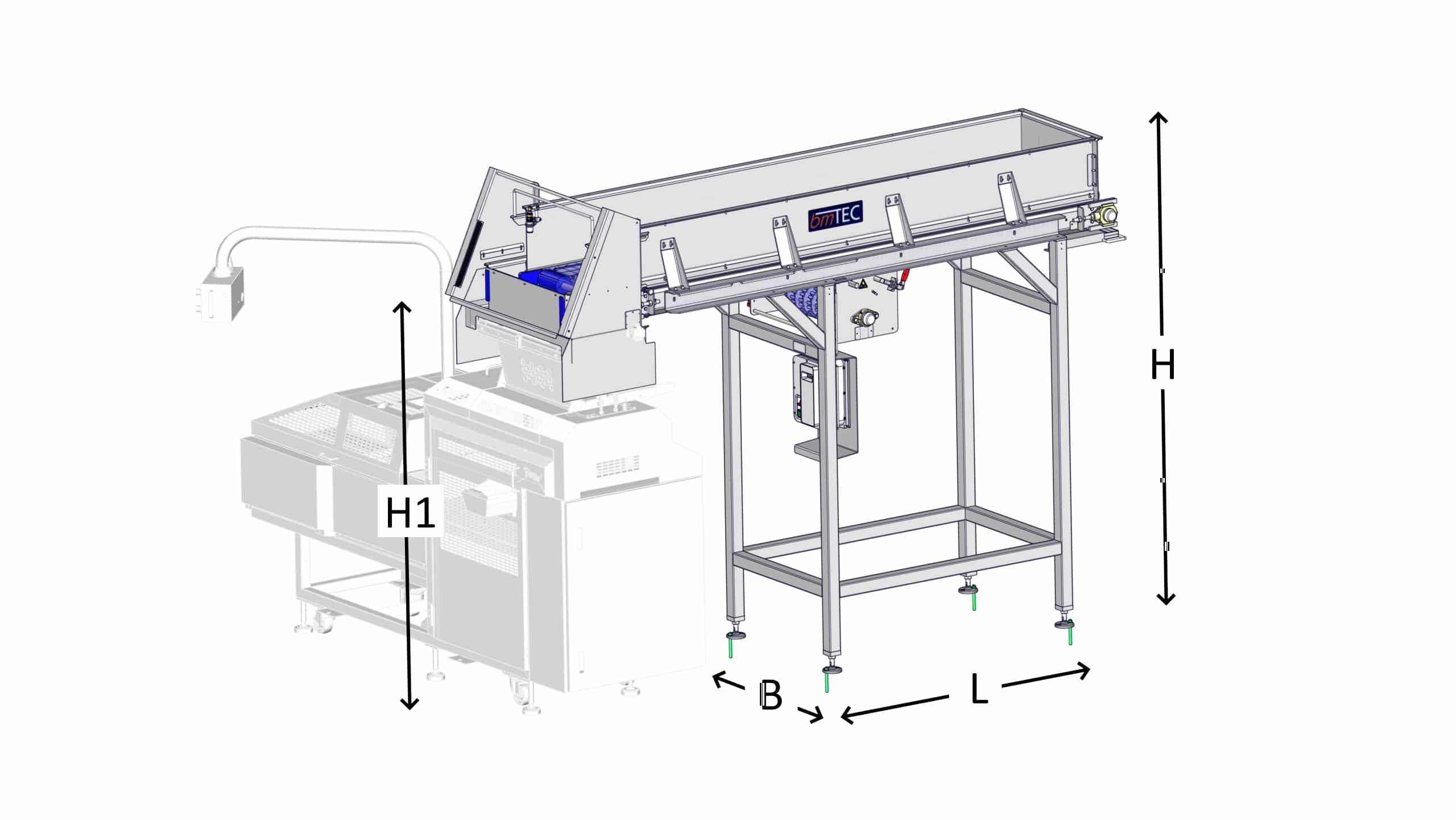

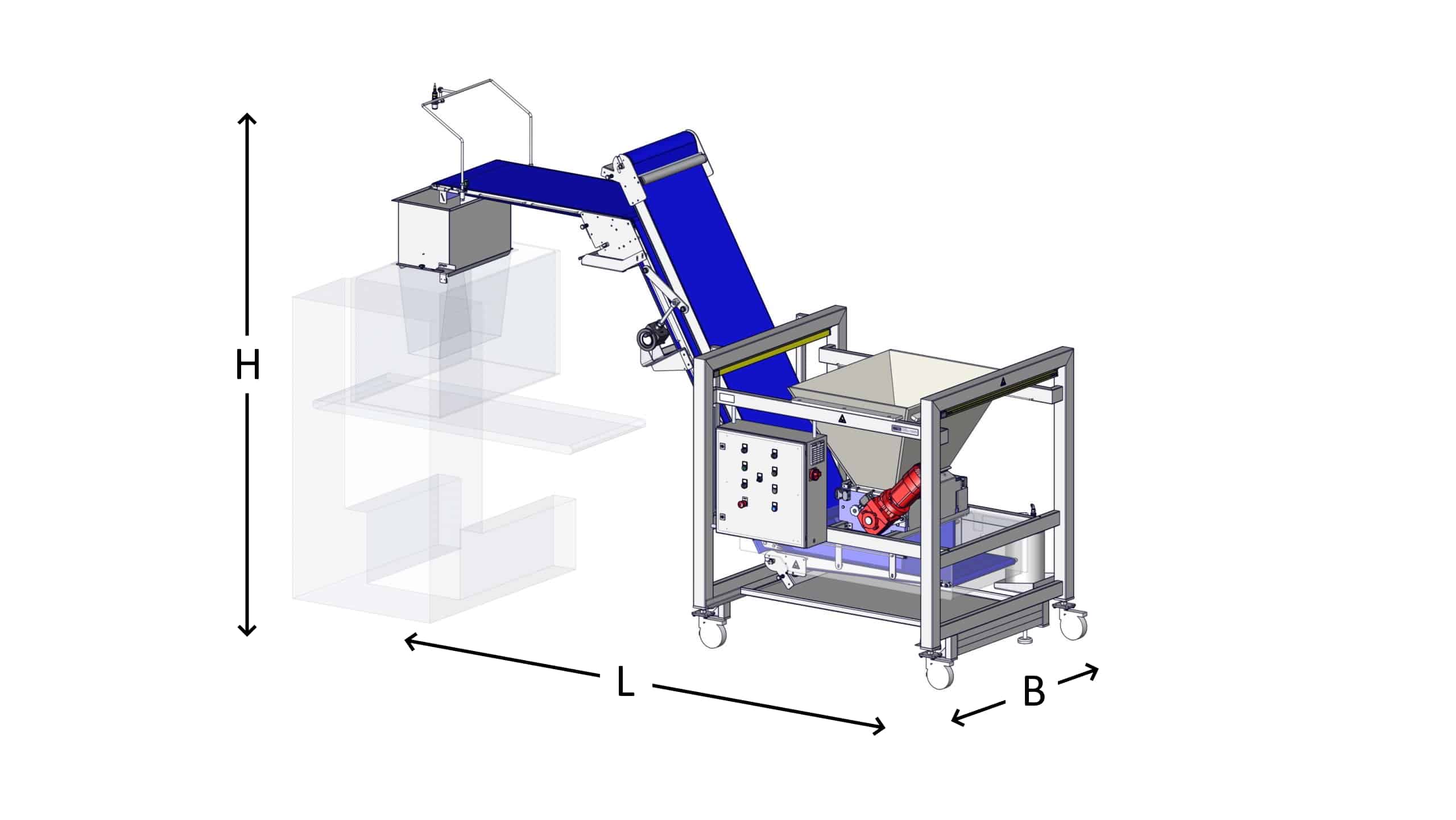

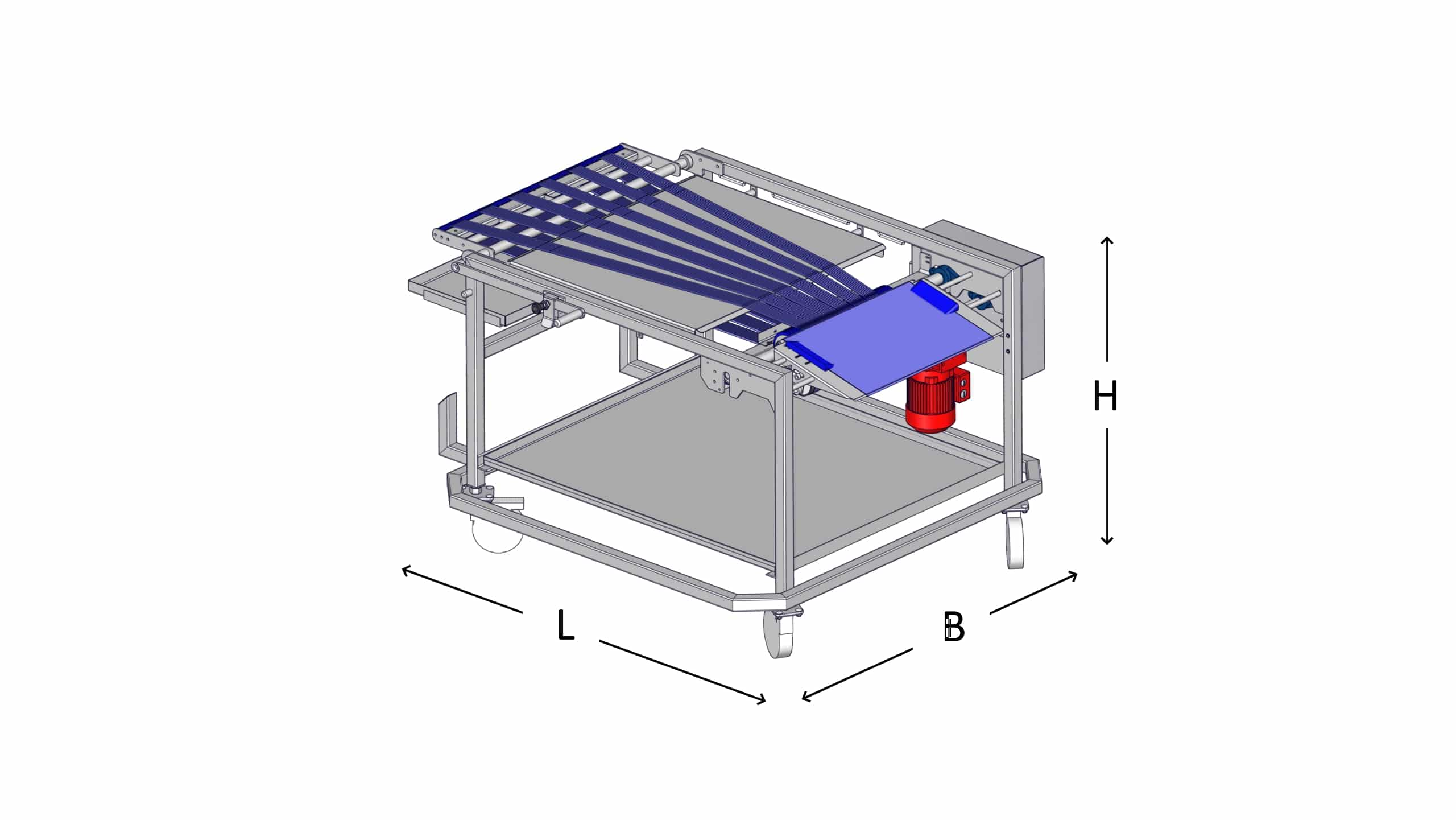

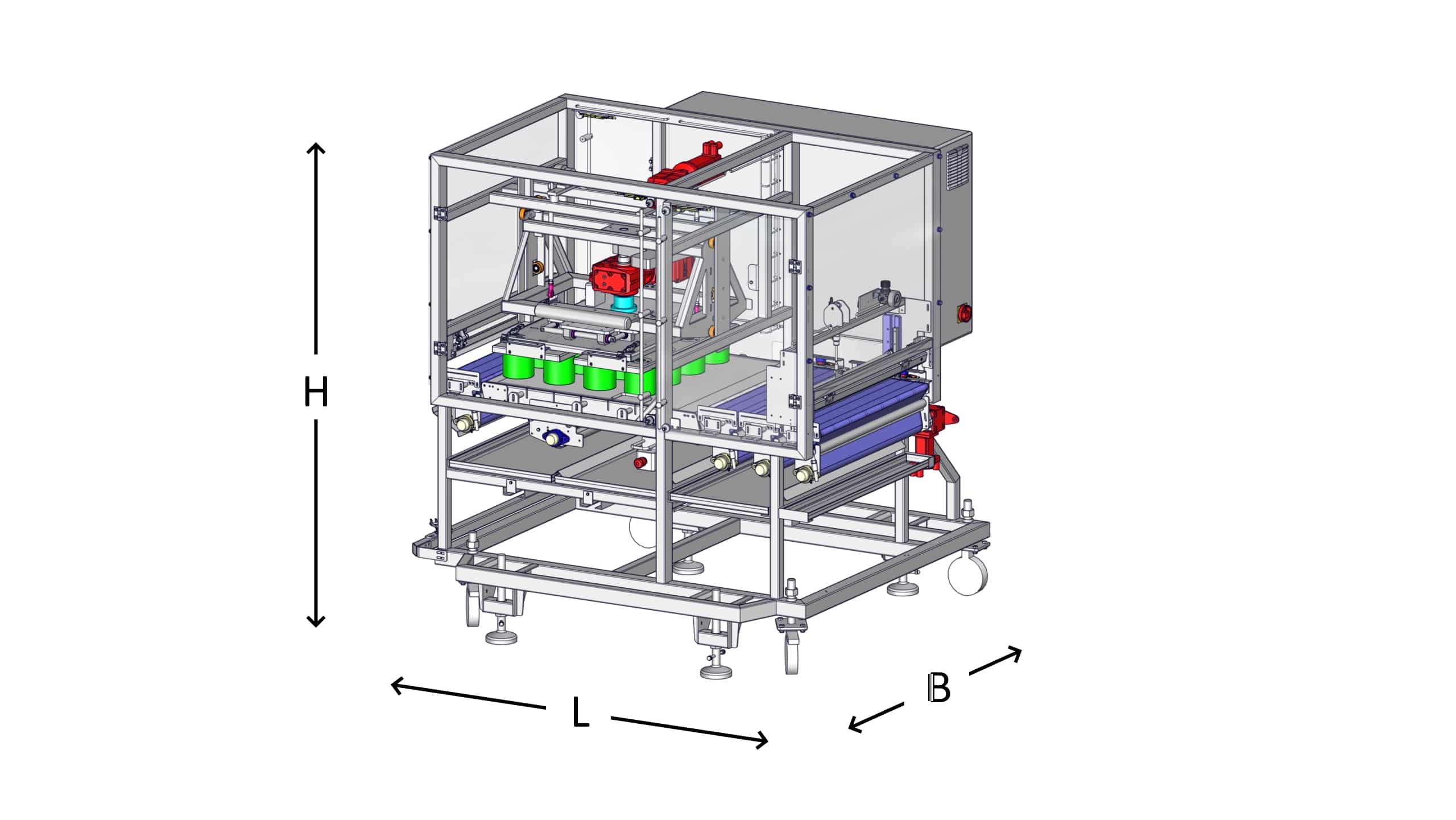

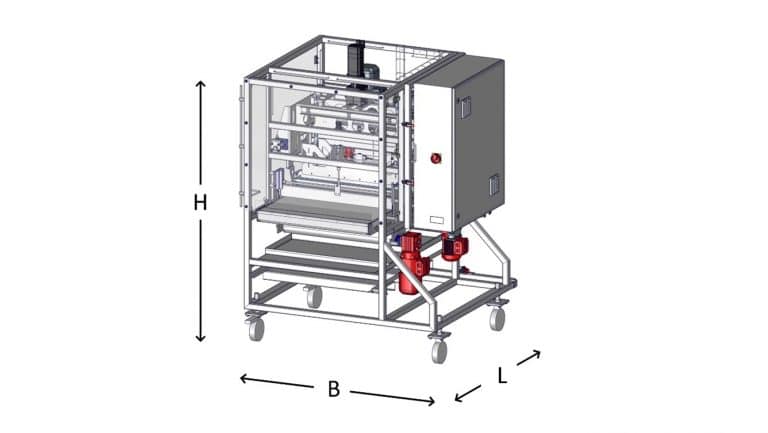

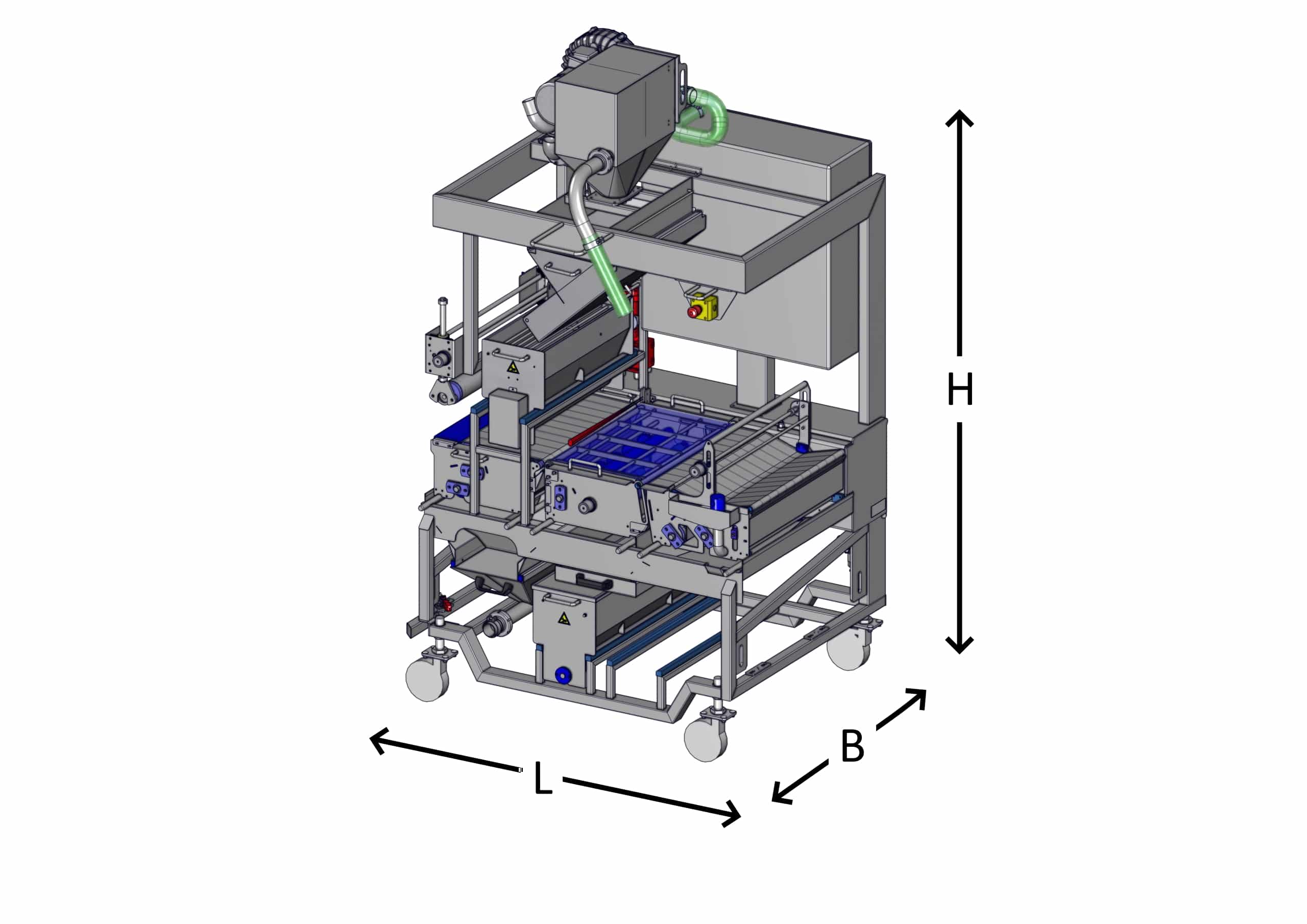

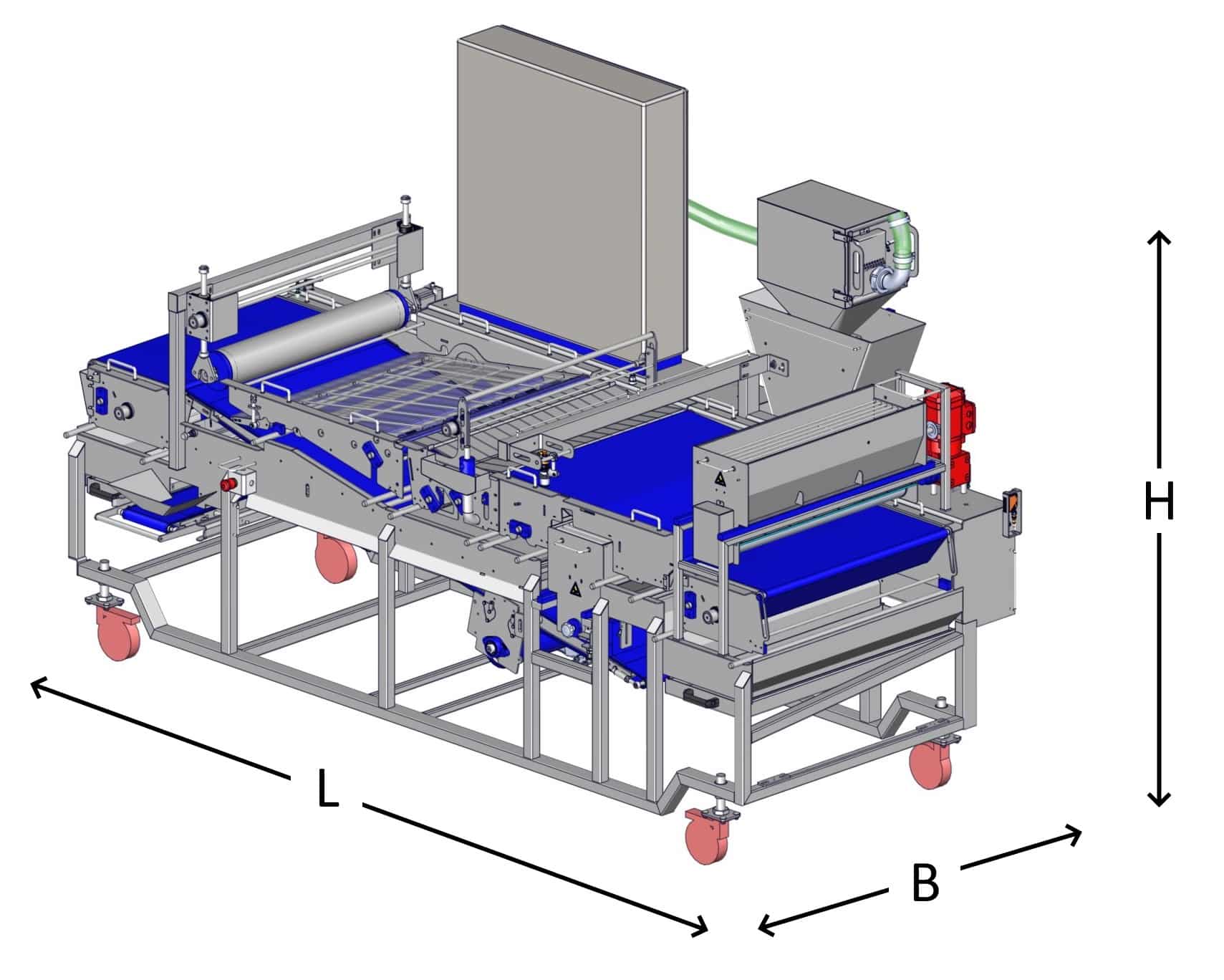

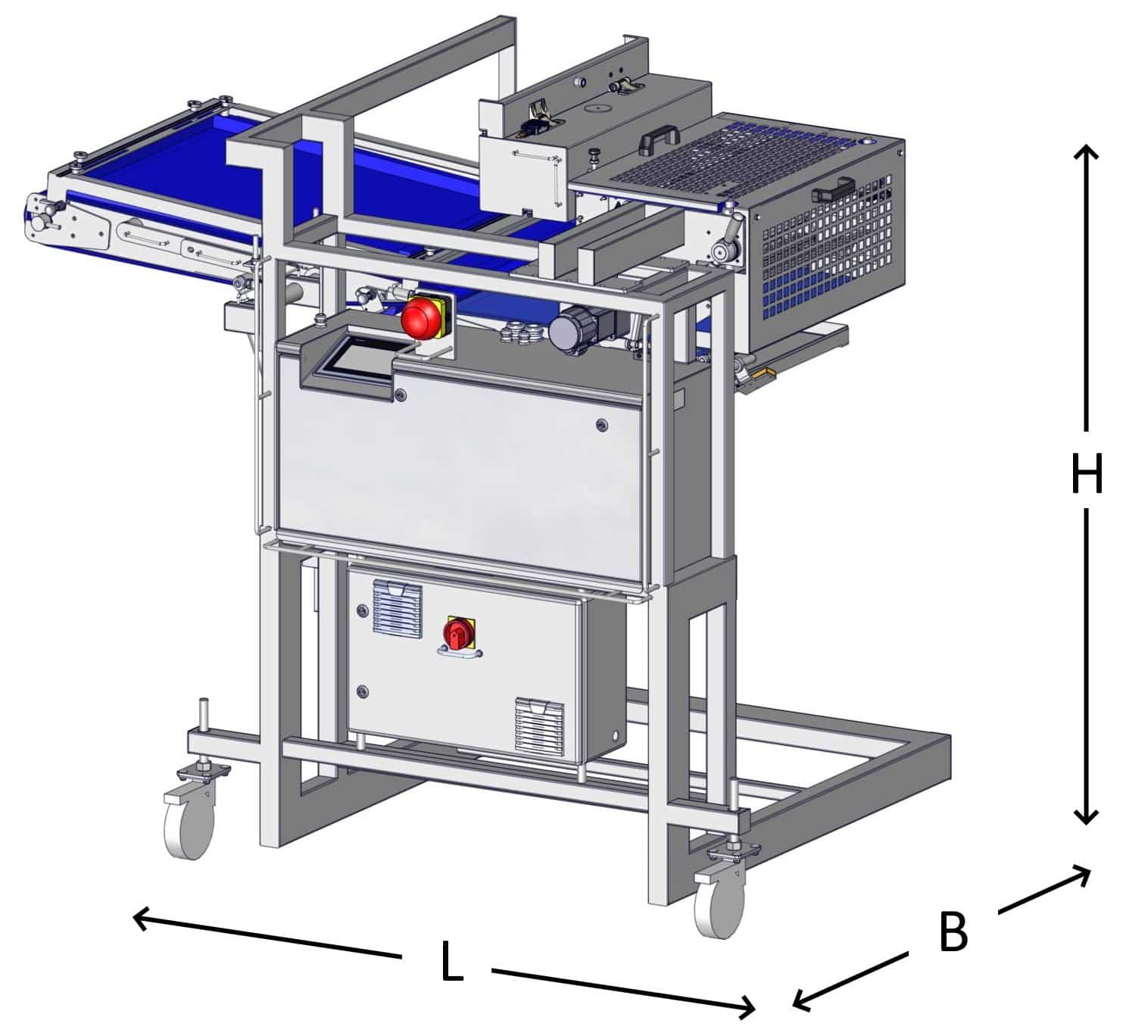

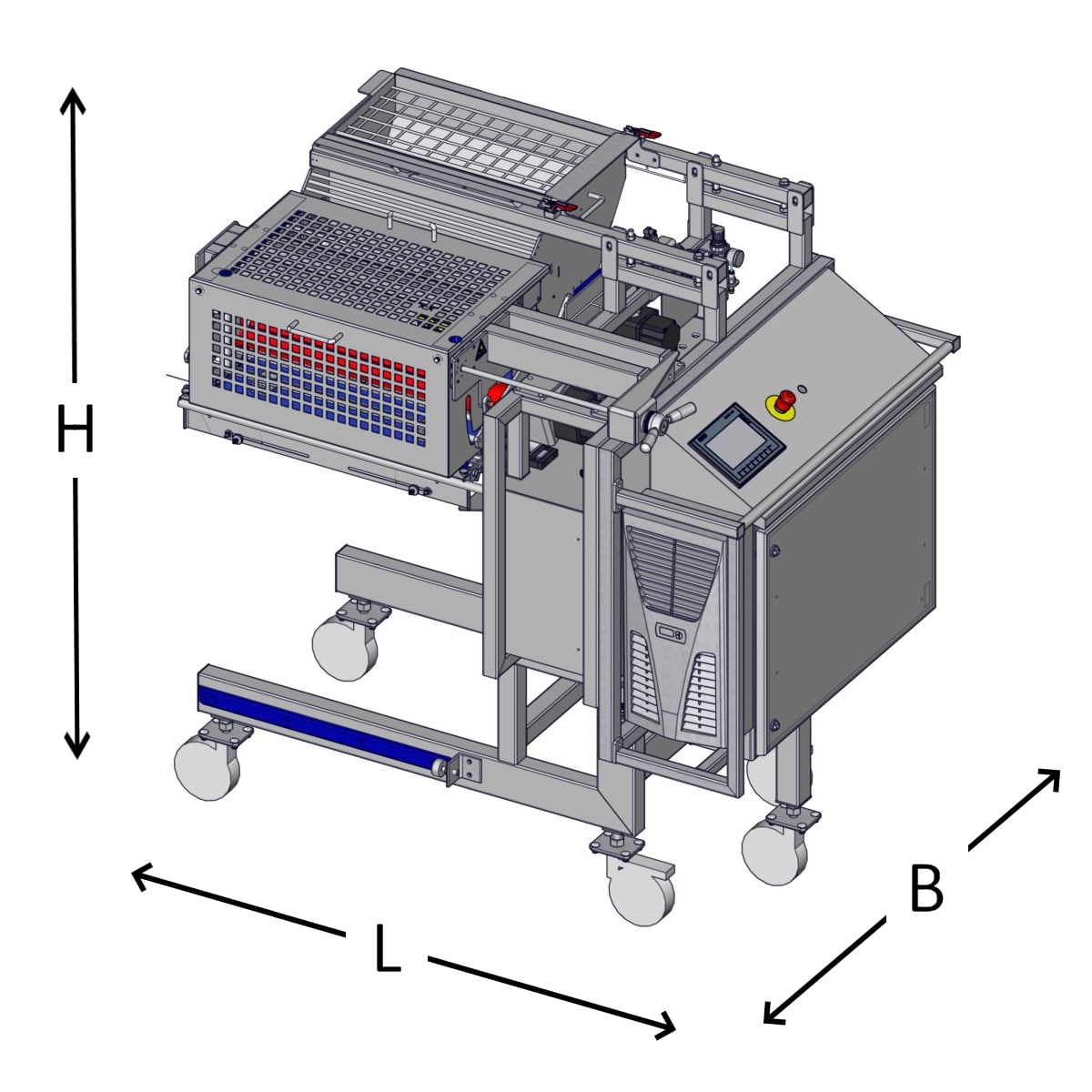

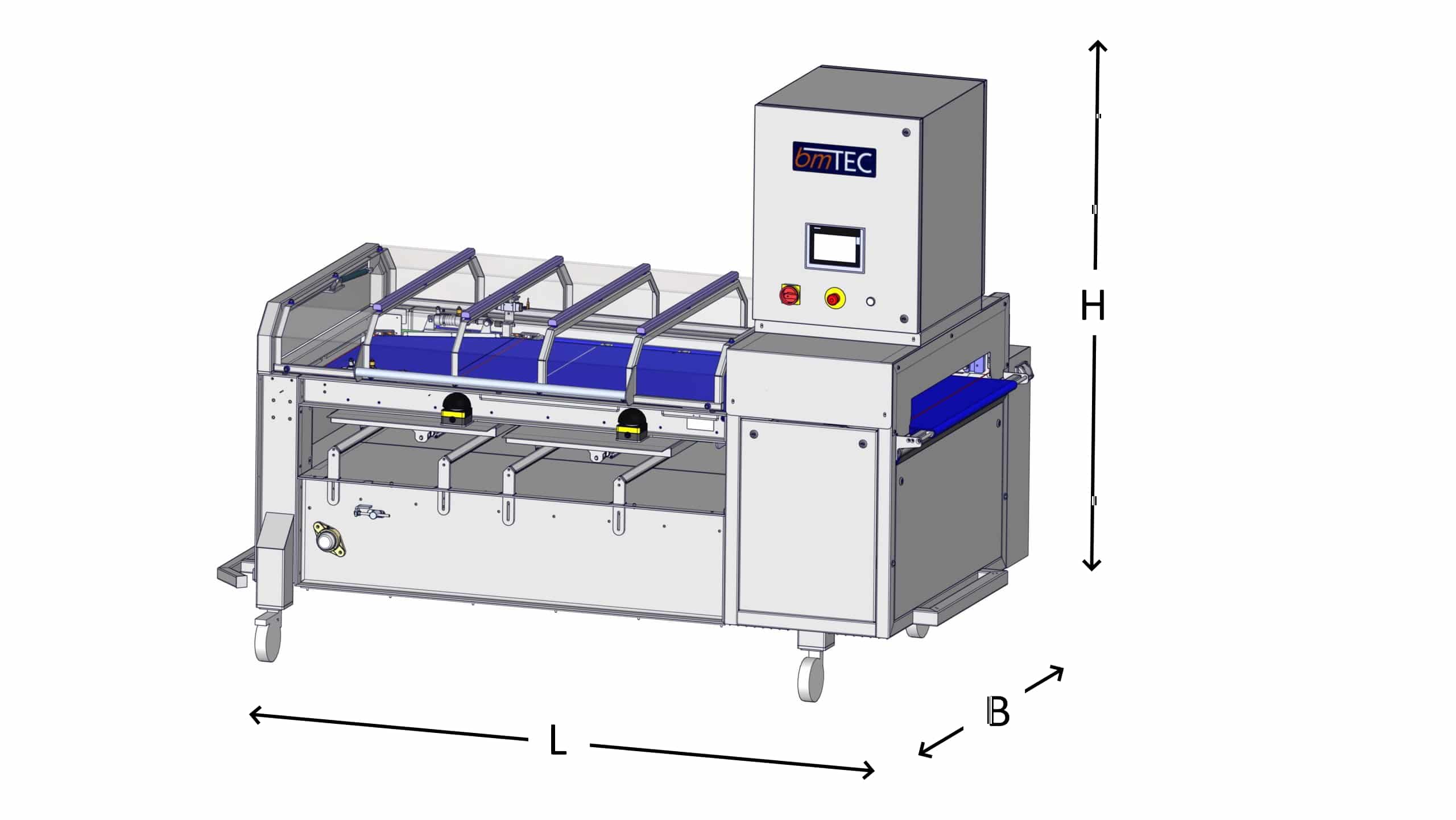

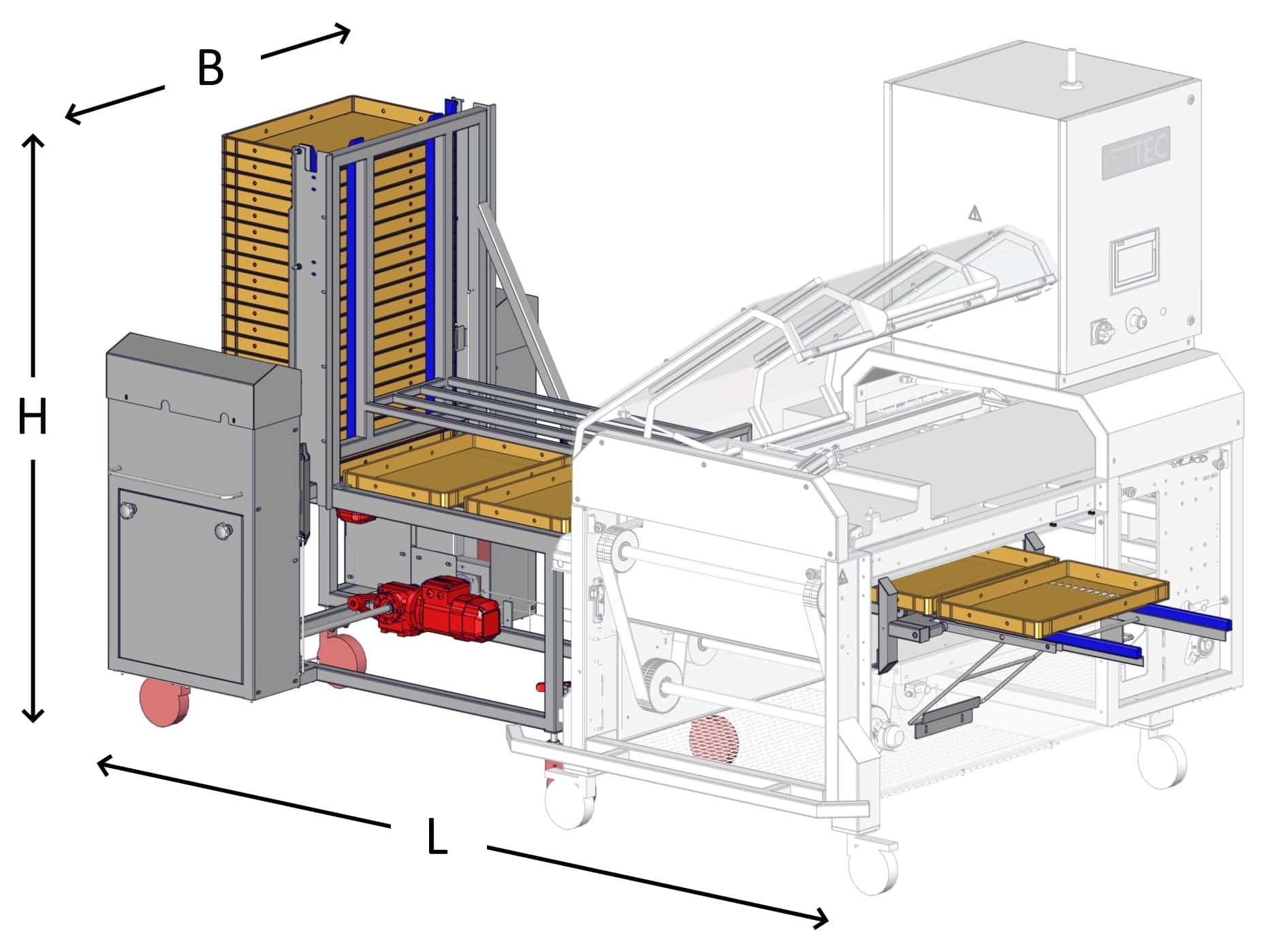

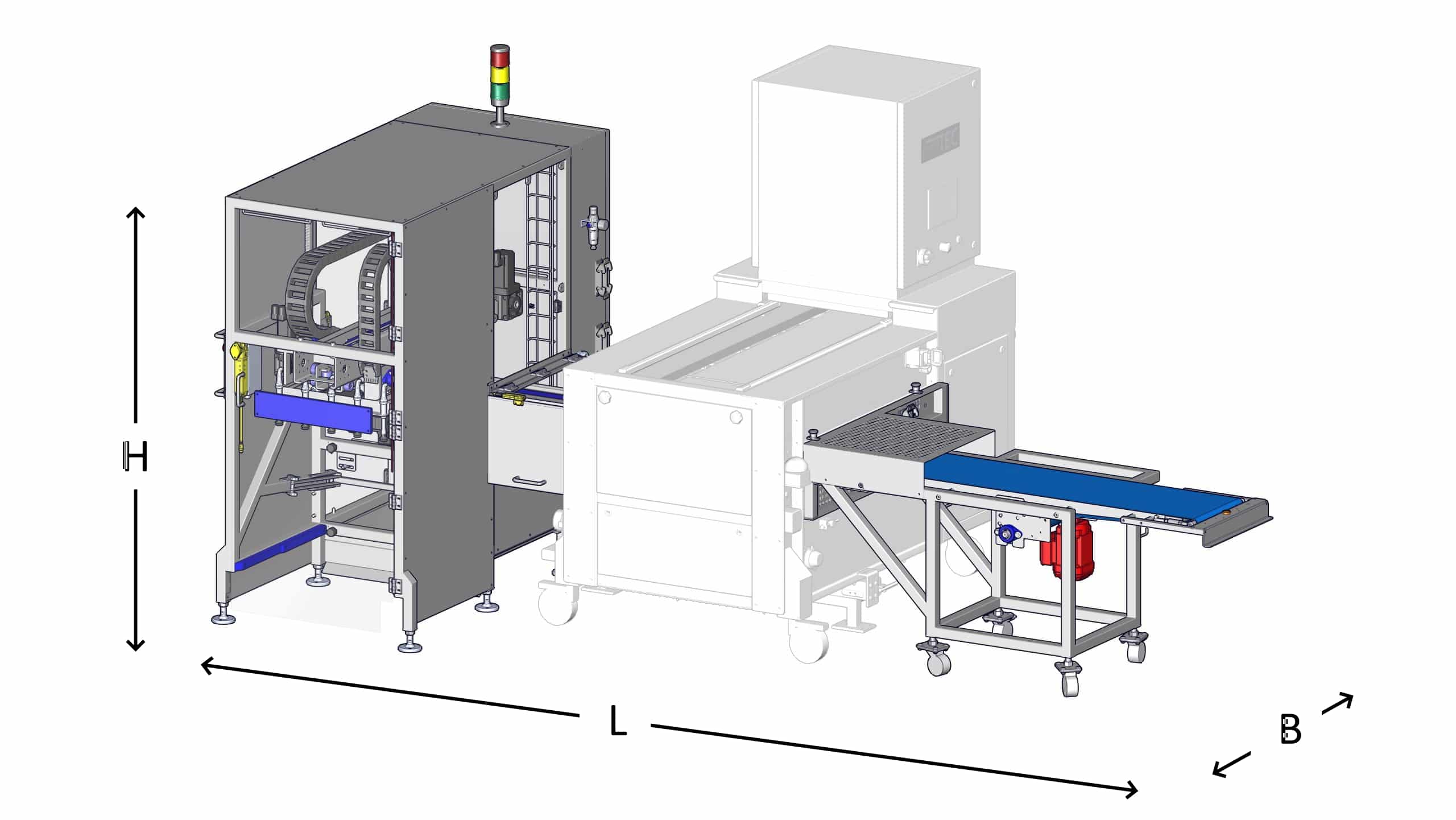

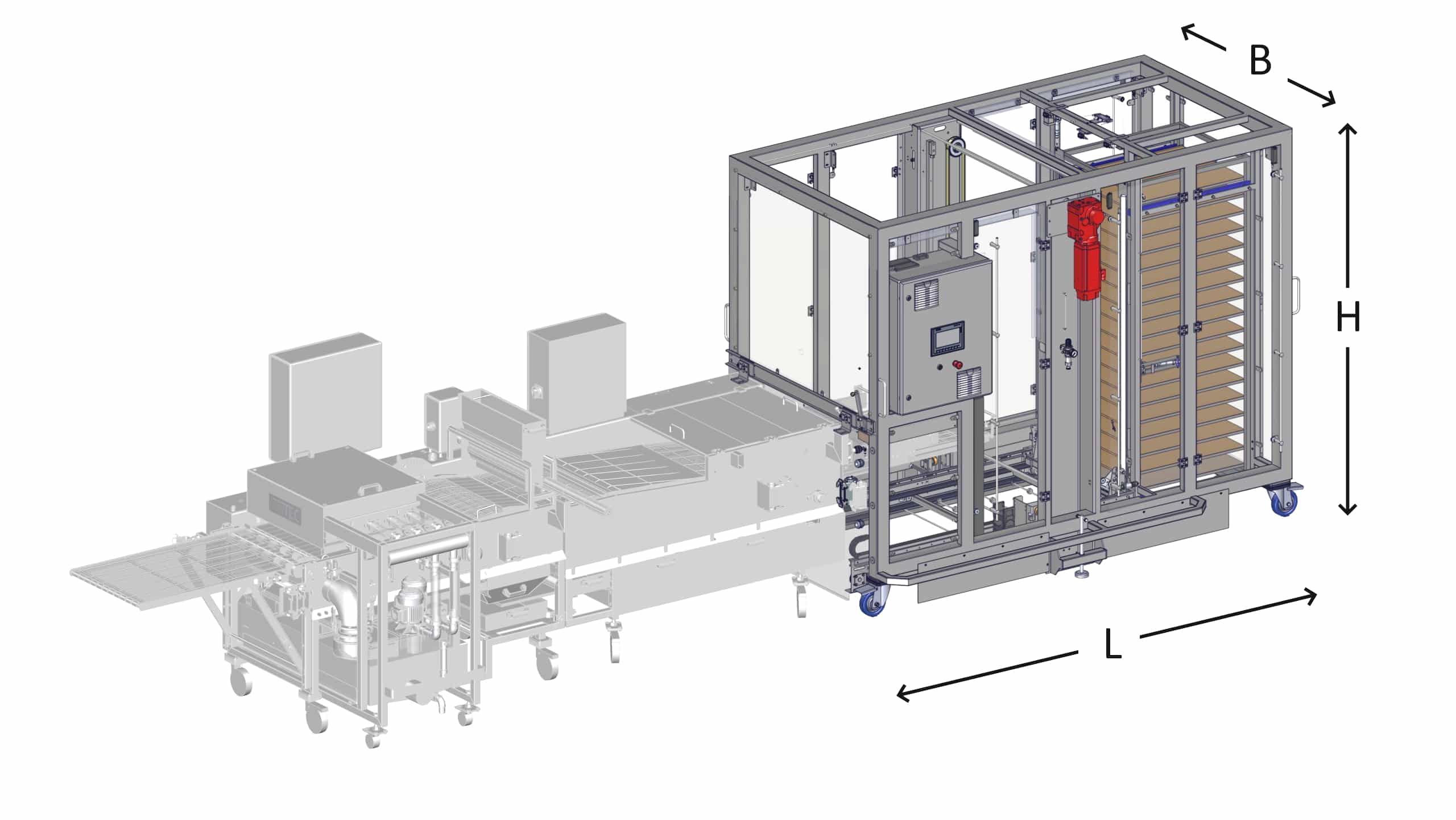

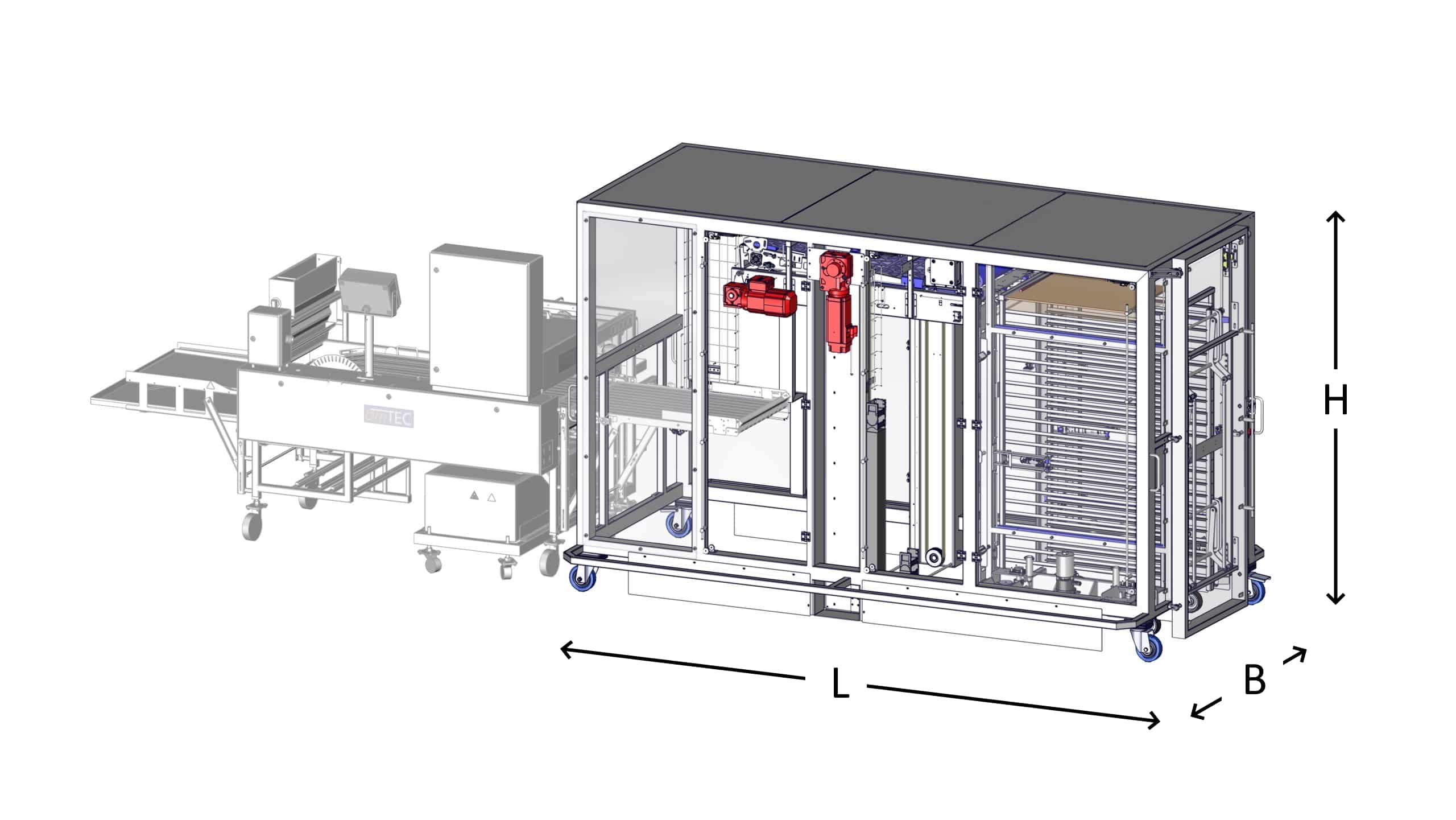

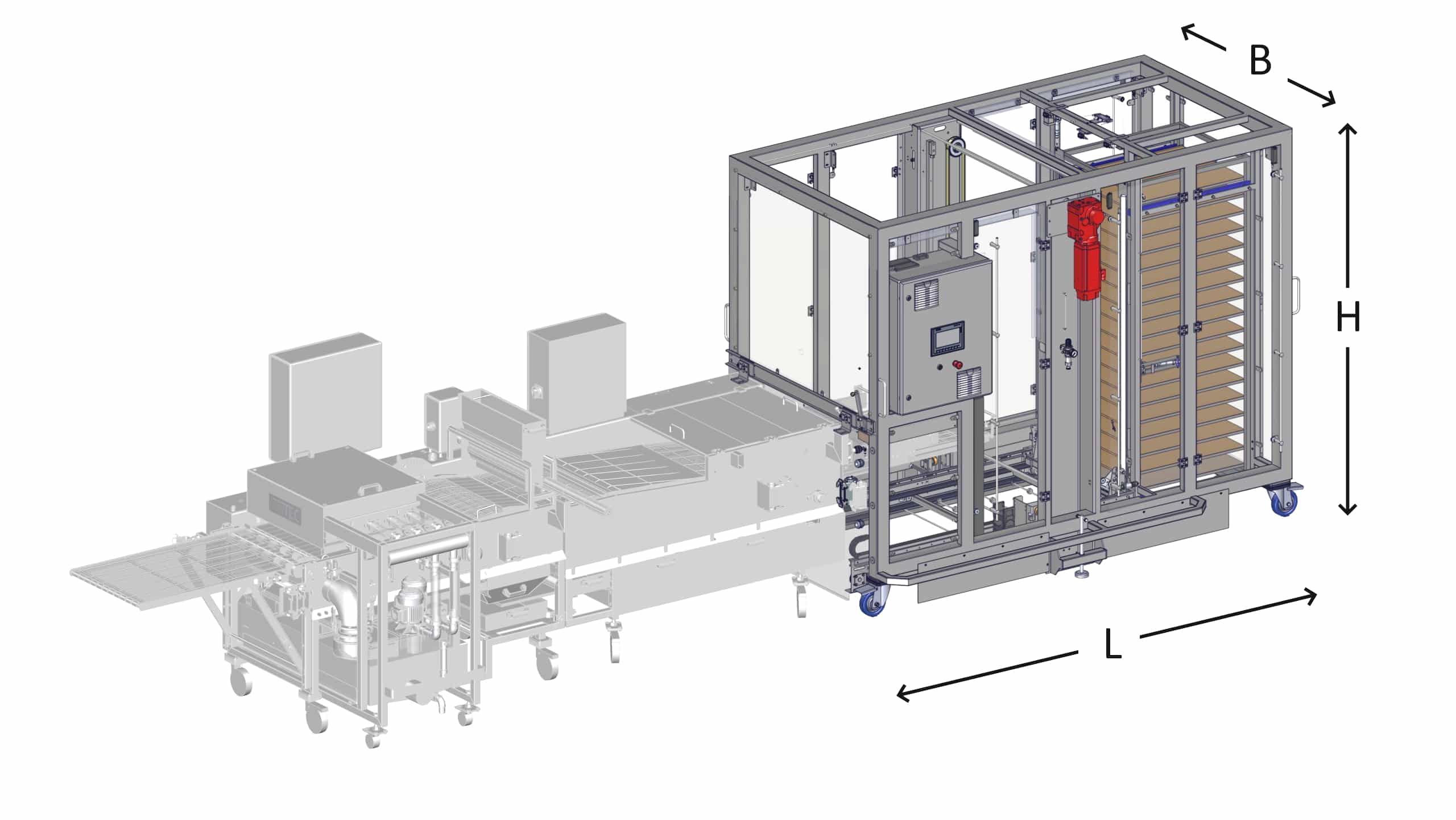

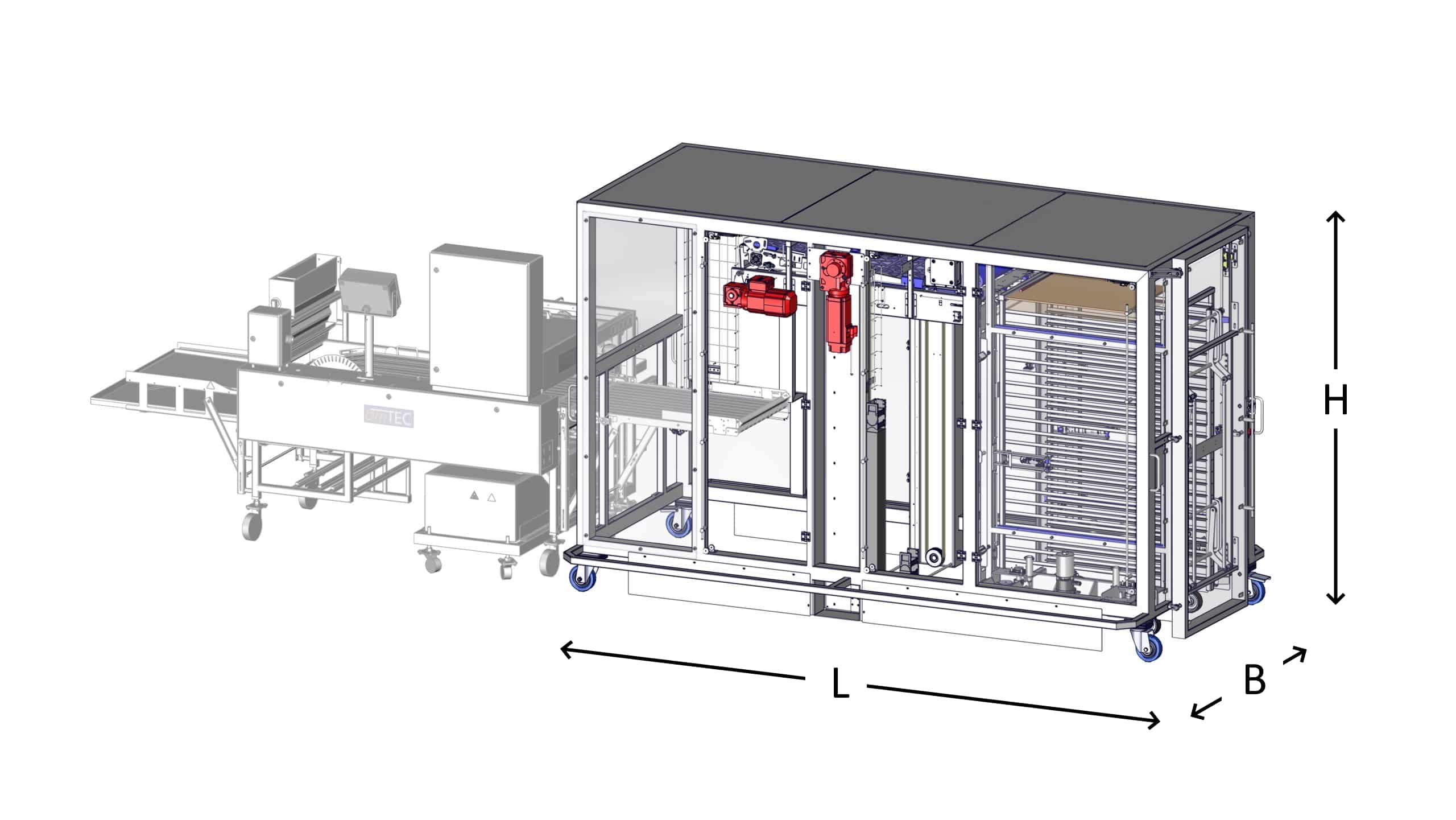

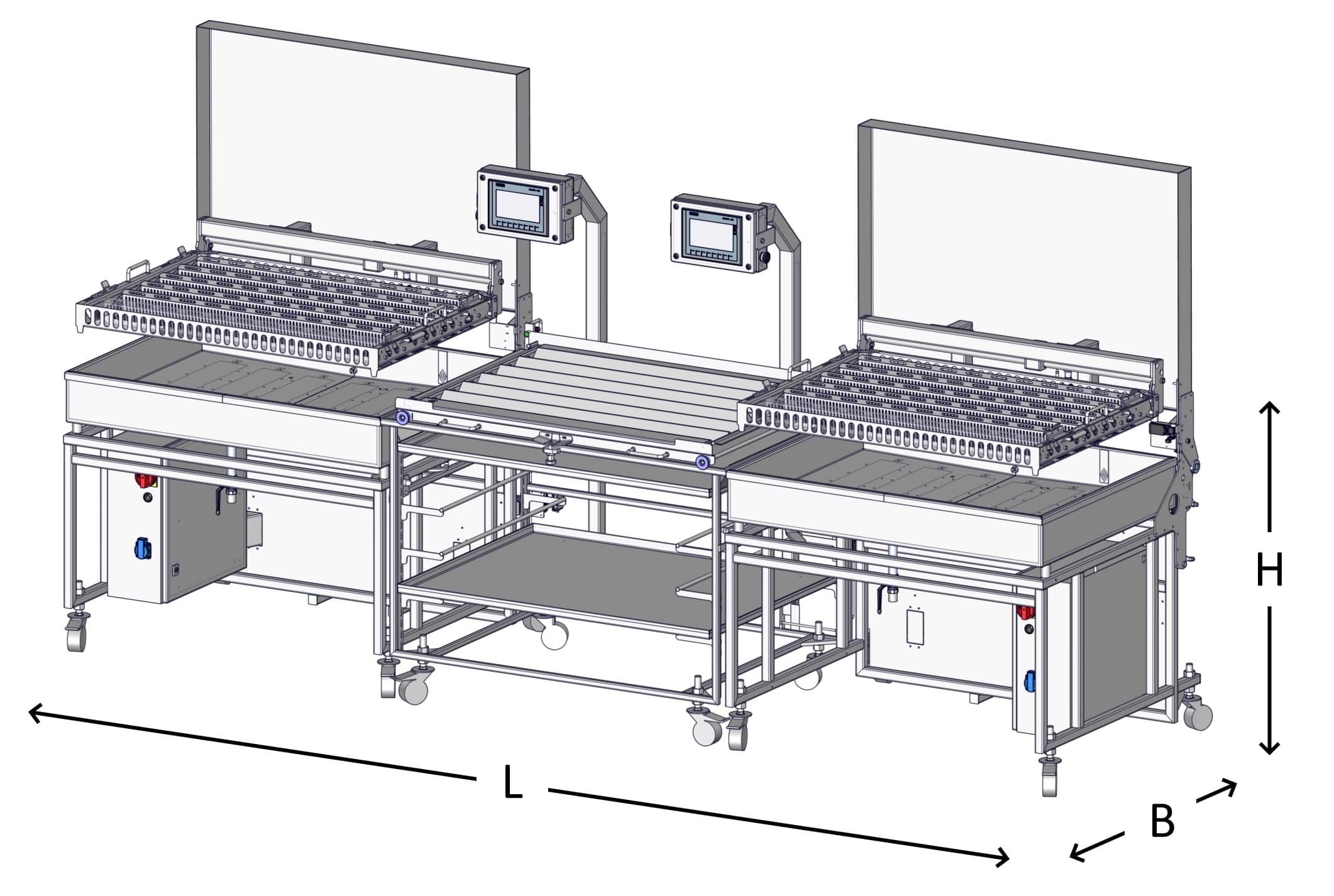

Daher bieten wir als bmTEC voll kompatible Module auch zum schrittweisen Ausbau einer qualitätswahrenden Automation z.B. bei Personalmangel oder steigenden Produktionsmengen. Die Module lassen sich in Summe zu einer vollständigen und leistungsfähigen Produktionslinie aus einer Hand zusammensetzen.